CNC machines are essential inside the die and mildew industry for building precise molds and dies used in casting, forging, and injection molding processes. These molds should fulfill stringent dimensional accuracy demands.

The price of CNC precision machining is usually a bit bigger than for standard machining approaches. Even so, the advantages the procedure offers allow it to be definitely worth the additional expenditure. Below are some of Those people Added benefits:

Within an interview, Yu to begin with mentioned that his corporation stopped all shipments to Bredikhin’s business after Taiwan imposed export limits.

You will find many alternative machines and equipment for precision machining because of the wide applications of the method. Several parts demand differing kinds of cutting, so A variety of cutting tools are already produced.

Precision machining sorts the basis of numerous industries, no matter if for tooling or making the final solution. Many of the applications of precision CNC machining are:

When smartphones are electronics, they depend on CNC machines a great deal that they require a Unique mention of their own. Nearly all smartphone construction is done with CNC manufacturing methods.

Market manufacturing industries aren't large like the ones outlined up to now. Nevertheless, They are really smaller to medium-scale manufacturing services depending on CNC machining for trustworthy parts.

With the Main of recent manufacturing is precision and performance; CNC Precision Machining performs an indispensable purpose right here. Used from aerospace to medical devices, it is now an integral technology.

Machining Method: After every little thing has become assembled, the more info CNC machine begins cutting, shaping, or drilling materials precisely alongside its programmed path with minimal human intervention demanded for your repetitive production of higher-precision products.

There exists plenty of a distinct style of CNC machine according to the applications and industrial needs. Similarly, Often industrial designers and mechanical engineers usually build some machines in-residence for in-residence demands. Working with stepper motors, motor controllers and G-codes can help them to acquire custom CNC machines.

CNC Milling CNC milling is to chop reliable plastic and metal materials into ultimate precision parts utilizing distinct axis milling procedures. Milling could be also referred to as a perfect method of making tooling for die casting and injection molding. Know more...

Nanotech Precision, LLC is about micro component machining, Which explains why we give attention to little and micro-sized Swiss turning and Swiss machining. With the industry development towards miniaturization, Nanotech Precision has produced verified capabilities to Swiss machine the smallest parts with a better degree of precision and consistency. Nanotech Precision makes use of Swiss turning machine tools created for Severe rigidity and procedure steadiness. Approach security is essential in machining health-related components, aerospace factors, or any time a superior degree of accuracy and repeatability is necessary.

Although precise CNC machining tools are very correct, they can't recreate merchandise Proportions particularly as they seem during the CAD blueprint. Machinists use tolerances.

CNC precision machining employs specialized processes and cutting tools to lessen the tolerances on the minimal values achievable. This brings about increased accuracy of the parts in comparison to the first blueprints.

Neve Campbell Then & Now!

Neve Campbell Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Yasmine Bleeth Then & Now!

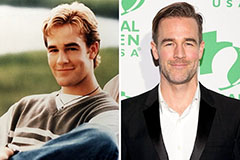

Yasmine Bleeth Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now!